Warum müssen die Radsätze von schienengebundenen Fahrzeugen geprüft werden?

Die Prüfung der Radsätze von schienengebundenen Fahrzeugen ist aus mehreren Gründen von entscheidender Bedeutung. Diese Prüfungen tragen wesentlich zur Sicherheit und Zuverlässigkeit des Schienenverkehrs bei, indem sie potenzielle Probleme frühzeitig erkennen und somit schwere Unfälle verhindern. Hier sind einige zentrale Aspekte:

Sicherheits- und Zuverlässigkeitsgründe

- Erkennung von Materialermüdung:

Radsätze sind extremen Belastungen ausgesetzt, die zu Materialermüdung führen können. Regelmäßige Prüfungen identifizieren Ermüdungserscheinungen, bevor sie zu Brüchen führen. - Überwachung von Verschleiß:

Verschleiß an den Laufflächen der Räder und anderen Komponenten des Radsatzes kann die Fahrsicherheit beeinträchtigen. Prüfungen ermöglichen die rechtzeitige Instandhaltung oder den Austausch abgenutzter Teile. - Aufspüren von Rissen:

Risse in den Rädern oder Achsen können katastrophale Folgen haben. Nicht-invasive Prüftechniken wie Ultraschall- oder Magnetpulverprüfung erkennen Risse frühzeitig. - Überprüfung der Schmierung:

Eine unzureichende Schmierung der Lager und anderen beweglichen Teile führt zu erhöhter Reibung und Verschleiß. Regelmäßige Kontrollen stellen sicher, dass alle Schmierstellen optimal versorgt sind.

Verbesserungen durch Messungen

- Optimierung von Design und Materialien:

Durch die Analyse der Messdaten können Schwachstellen im Design erkannt und Verbesserungen vorgenommen werden. Dies führt zu langlebigeren und leistungsfähigeren Radsätzen. - Leistungs- und Haltbarkeitsverbesserung:

Messungen liefern wichtige Informationen zur Verbesserung der Haltbarkeit und Leistungsfähigkeit der Radsätze, was die Lebensdauer der Komponenten verlängert und die Betriebskosten senkt. - Minimierung von Rollgeräuschen:

Schwingungs- und Geräuschmessungen helfen dabei, Maßnahmen zur Reduktion von Rollgeräuschen zu entwickeln, was den Komfort für die Fahrgäste erhöht und die Umweltbelastung verringert.

Sensoren:

- Dehnungsmessstreifen (350 Ω): Zur Überwachung von Belastungen und Spannungen im Radsatz.

- Temperatursensoren: Um Temperaturänderungen zu erfassen, die auf Schmierprobleme oder übermäßige Reibung hinweisen.

- IEPE-Schwingungssensoren: Zur Messung von Vibrationen, die auf Unwuchten, Lagerprobleme oder andere mechanische Defekte hinweisen.

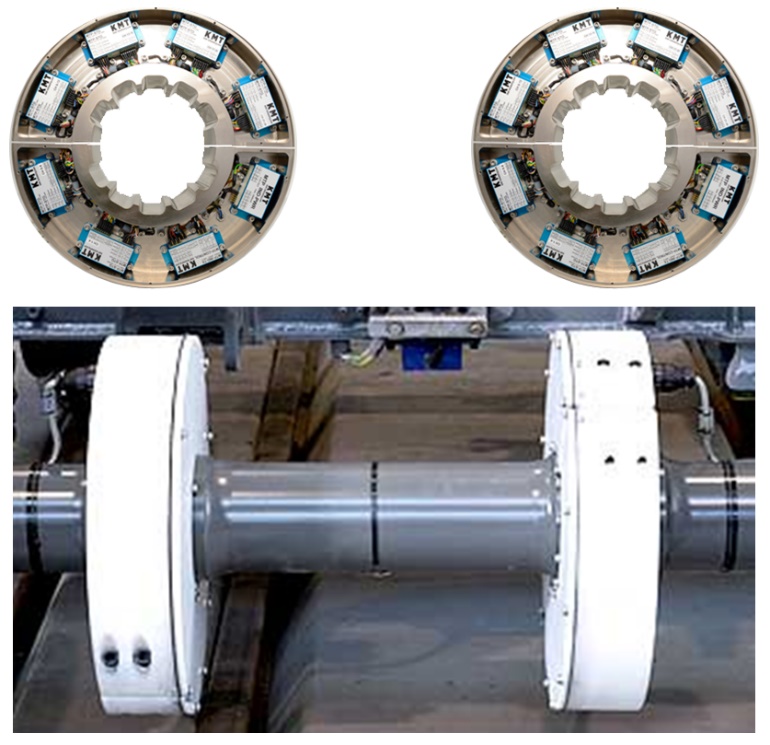

Stromversorgung:

Eine stabile und batteriegestützte Energieversorgung ermöglicht lange Messaufzeichnungen. Die induktive Energie- und Datenübertragung über einen mehrfach gewickelten Kupferdraht stellt eine zuverlässige Verbindung sicher, auch unter rauen Bedingungen.

![[Translate to Deutsch (de):] Montagebeispiel für die Telemetriemodule und die Spulen für die Signalübertragung und Spannungsversorgung](/fileadmin/Public/Applications/Rail/Stromversorgung.jpg)

Umgebungsbedingungen:

- Schutz gegen Spritzwasser, Öl, Staub: Die Komponenten müssen robust und gegen Umwelteinflüsse wie Wasser, Öl und Staub geschützt sein.

- Stoß- und Vibrationsbeständigkeit: Geräte und Sensoren müssen in der Lage sein, schwere Stöße und starke Vibrationen zu überstehen.

- Temperaturbeständigkeit bis zu 85°C/185°F: Die Ausrüstung muss in der Lage sein, hohen Umgebungstemperaturen standzuhalten, ohne an Leistung oder Zuverlässigkeit einzubüßen.

Zusätzliche Herausforderungen:

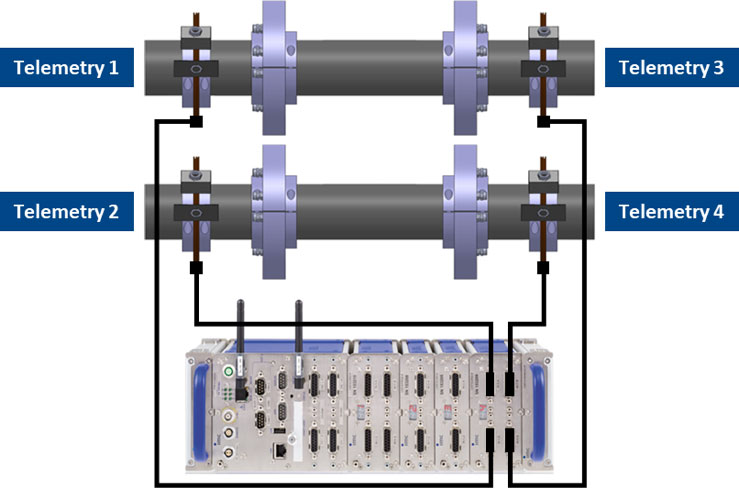

Um die Anwendungsbedingungen für ein System im Eisenbahnsektor mit einem Wellendurchmesser von 110 mm bei einer maximalen Drehzahl von 1500 U/min zu erfüllen, und gleichzeitig die besonderen Herausforderungen im Umgang mit Hochspannungen und unterschiedlichen Potentialen der Sensoren und Messverstärker zu berücksichtigen, müssen mehrere Aspekte beachtet werden. Diese Aspekte umfassen die mechanische Haltbarkeit, elektrische Isolierung und Schutzmaßnahmen sowie die Datenerfassung und Signalverarbeitung.

Fazit

Regelmäßige und gründliche Prüfungen der Radsätze sind unerlässlich, um die Sicherheit und Zuverlässigkeit des Schienenverkehrs zu gewährleisten. Durch den Einsatz modernster Messtechnologien und robuster Systemaufbauten können potenzielle Probleme frühzeitig erkannt und behoben werden, was zu einer erheblichen Verbesserung der Betriebsleistung und -sicherheit führt.

![[Translate to Deutsch (de):] Montagebeispiel der kundenspezifischen Gerätekonfiguration](/fileadmin/Public/Applications/Rail/Kundenspezifisches-Gehaeuse_-direkt-auf-der-Welle-montiert-3-min.jpg)